IWATA, April 05, 2018—Yamaha Motor Co., Ltd. (Tokyo:7272) announced today that it will exhibit for the first time at the HANNOVER MESSE 2018, a B to B industrial technology trade show to be held in Hannover, Germany, from Monday, April 23 to Friday, April 27, 2018. Based on the theme of “Fully-Digitalized Production through Robot Transport,” the Yamaha Motor booth will showcase the overall construction of Fully-Digitalized Production lines, including transport processes.

The HANNOVER MESSE is the world’s leading industrial trade fair, at which leading-edge industrial technology and products are gathered in one place. (The 2017 event saw exhibits held by approx. 5,000 companies attracting around 220,000 visitors). The Yamaha Motor booth at the HANNOVER MESSE will feature the Advanced Robotics Automation Platform, as well as an operation demonstration of the Platform and the YK400XR SCARA robot, showcasing the high-speed capability and precision of Yamaha robotics technology to a broad cross-section of the European market.

Overview of HANNOVER MESSE 2018

http://www.hannovermesse.de/home

| Event Period | : | April 23 to 27, 2018 | |

| Venue | : | Hannover Exhibition Grounds, Germany | |

| No. of Exhibitors | : | Approximately 5,000* | |

| No. of Attendees | : | Around 220,000 people* | *Previous event (2017) |

Yamaha Motor Exhibit Outline

| Exhibit Space | : | Hall17, B06 | |

| Details | : | ◎Exhibition and demonstrations Advanced Robotics Automation Platform YK400XR |

Contact info

Oumayma Grad

Marketing Communications Manager

Hansemannstraße 12

41468 Neuss

Germany

Office: +49 2131 2013 538

Mobile: +49 1517 0233 297

Fax: +49 2131 2013 550

Email: oumayma.grad@yamaha-motor.de

Web: www.yamaha-motor-im.eu

Models to be Exhibited by Yamaha Motor

Advanced Robotics Automation Platform

This new robotics system enables automation of complex advanced production facilities rapidly and at low cost. The system enables integrated control in one unit of the multiple robots and peripheral devices necessary for production facilities, reducing wasted time through the full digitalization of facilities.

ARAP Product Website:

https://www.yamaha-motor.co.jp/robot/platform/en/

Explanatory video:

https://youtu.be/r_x_WSFj4rc

YK400XR

This SCARA robot features both high quality/functionality and excellent cost-performance. These robots deliver outstanding high rigidity, high-speed capability, and high-accuracy capability. They are utilized across a wide range of production processes, from production facilities for electrical/electronic components and compact precision machinery parts requiring precision assembly, through to transfer and transport in large automotive component assembly.

YK400XR Product Website:

https://global.yamaha-motor.com/business/robot/lineup/ykxg/

Applications:

https://global.yamaha-motor.com/business/robot/lineup/application/ykxg/

Introduction of Features:

https://global.yamaha-motor.com/business/robot/lineup/ykxg/small/yk400xr/

Demonstration video:

https://youtu.be/5b7JbiONZvY

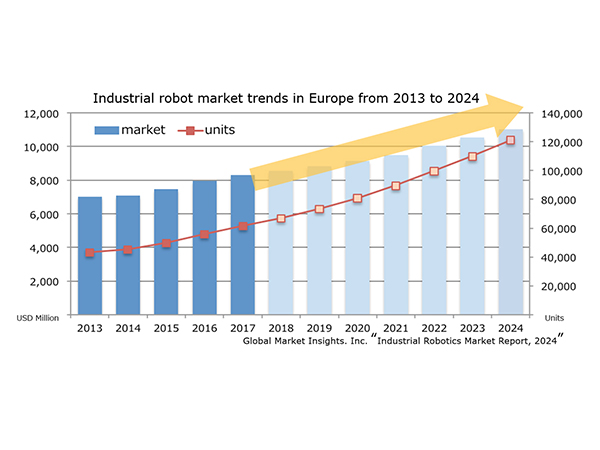

Industrial Robot Market Overview

Driven by rising wages and increased quality requirements in China and emerging markets, as well as the decreasing working-age population in Japan and Europe, the global robot market has followed a growth trend, which is expected to continue. The average annual growth rate for the 2017 to 2024 period is forecast to grow at 4.2% on a monetary basis, and at 10.2% on a unit basis, with market expansion expected to continue in the future.

History of Yamaha Motor Industrial Robots

| 1974 | : | Yamaha Motor begins research and development into industrial robots in order to streamline production and increase machining precision in its own motorcycle factories |

| 1976 | : | SCARA robots introduced to Yamaha Motor motorcycle production lines |

| 1981 | : | Industrial Robots business established. External sales begin |

| 1984 | : | IM Business Unit established (Yamaha Motor Hamakita Plant) / SCARA robot sales begin overseas |

| 1991 | IM Technology Center completion (Sodecho, Hamamatsu city, Shizuoka Prefecture) | |

| 2006 | IM Technology Center and factory expansion | |

| 2013 | : | China (Suzhou City) sales office established Linear conveyor module LCM100 launched |

| 2016 | : | Advanced Robotics Automation Platform integrated controller (PLC) launched |

| 2017 | : | New Robotics Business building begins operation |

Yamaha Motor’s lineup of industrial robots ranging from industrial robots to controllers, which powerfully support the automation of production sites, is rich in variation. YMC builds on these strengths to pursue greater efficiency and quality in increasingly complex, diverse, and high-speed production sites.

About YAMAHA Robotics FA Section

Yamaha Factory Automation Section (FA Section), a subdivision of Yamaha Motor Robotics Business Unit in Yamaha Motor Corporation, is focused on delivering flexible, high-accuracy industrial robots for precision automation challenges.With its roots in the introduction of robot technology to Yamaha motorcycle assembly activities, the division has over 40 years’ experience solving automation challenges from factory-scale to micron-level. Yamaha’s industrial robots are now trusted by leading corporations worldwide, in activities as diverse as semiconductor fabrication and assembling electronic products, domestic appliances, automotive components, and large liquid-crystal panels.

Yamaha FA Section offers a unified range of solutions for robotic assembly, including single-axis robots, SCARA, cartesian, and articulated robots. Innovations such as the LCM100 linear conveyor module; a smoother, space-saving and more versatile successor to conventional belt and roller conveyors continue to set the pace in factory automation. Core robotic technologies as well as key components and complete robot systems are all produced in-house, ensuring consistent quality and control over lead-times.

Headquartered in Hamamatsu, Yamaha FA Section serves customers globally through its worldwide sales network spanning China, Taiwan, Korea, south Asia, north America, Australia/New Zealand, and Europe.

www.yamaha-motor-im.eu