Yamaha Motor Europe announced today that it will launch the RCX-Studio 2020 support software for the RCX3 Series of robot controllers on May 14, 2020. This new product adds new functions such as a 3D simulator and program templates (automatic sample generation) to the existing RCX-Studio Pro software, and also features usability enhancements.

RCX-Studio 2020 enables on-screen equipment layout work, teaching, program creation, debugging, etc. even if robots are not connected. By doing so, this software makes a significant contribution to accelerating robot system setup and further reducing operator workload.

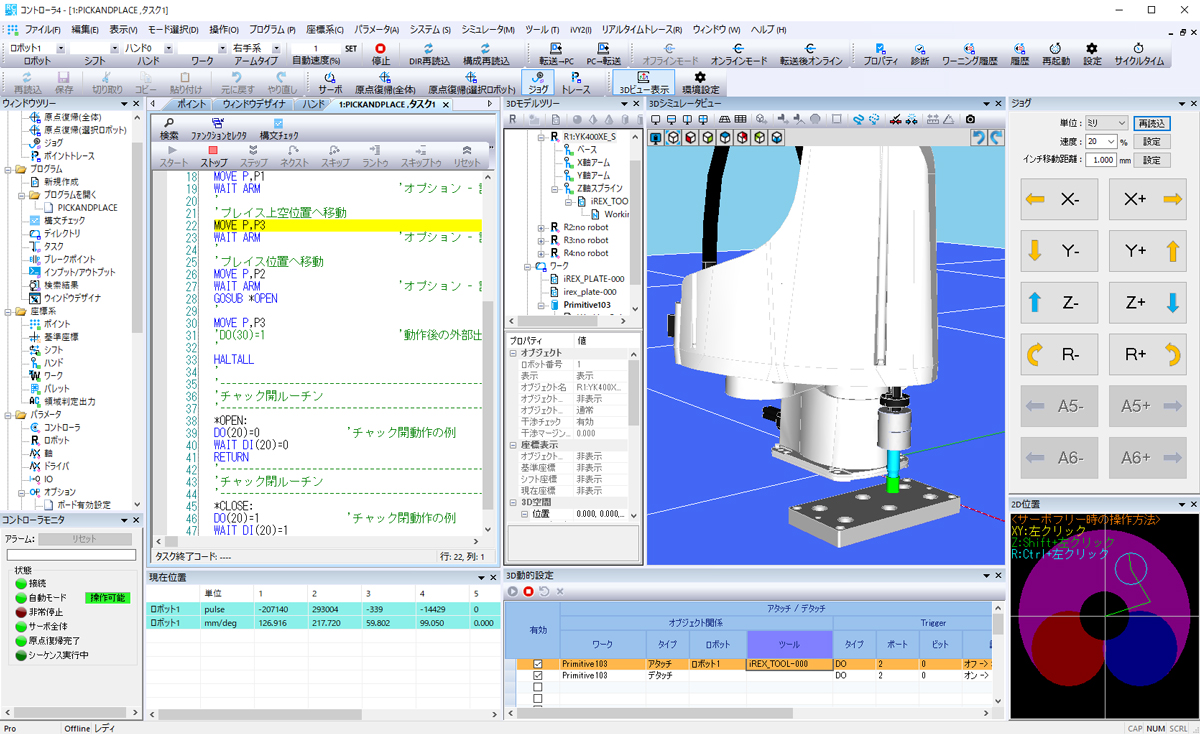

RCX-Studio 2020 controller support software, part of the RCX3 Series (operation screen sample image)

RCX-Studio 2020 Main Features

1) 3D simulator function

Shows the robots and peripheral devices in 3D, simulating robot operation on your computer. The simulation feature allows users to work on robot layout, teaching, debugging, etc. even if robots are not connected, checking on-screen for interference between robots and peripheral devices in advance of equipment startup. Prior evaluation of layout enables prevention of interference with customers’ production equipment.

- 3D CAD incorporation: Compatible with STL, Wavefront OBJ, VRML2.0, and STEP

- Jog movement and teaching

- Expression of peripheral devices and workpieces with simple shapes (primitive)

- Teaching using 3D CAD data characteristics*

- Robot trajectory display

- Robot and peripheral device interference checking (also handles situations where workpieces are moved manually)

- Handles multiple robots (up to four)

*Pro version only. Compatible formats: AP203, AP214

RCX-Studio 2020 includes program templates for ten popular applications. Program templates can be automatically generated simply by following the operation order steps. Not requiring command input makes program creation easier, enabling significant reductions in program creation time.

Compatible Applications:

- Pick and place

- Palletizing

- Coating

- Switching execution programs

- Conveyor tracking

- Pallet picking using AI vision

- Coating using AI vision

- Correcting pickup deviations using AI vision

- Correcting pickup deviations using AI vision and correcting placement position

- Correcting pickup deviations using AI vision and correcting placement position (without master)

*Pro version only. Compatible formats: AP203, AP214

3) Custom window creation function

GUIs for operators such as those shown on control panels can be created easily. Focusing on only the functions necessary for operations means that problems such as data deletion and overwriting due to mistaken operation can be prevented, and also enables creation of operation screens tailored to customers’ particular equipment.

4) Other existing functions

RCX-Studio 2020 inherits the rich functionality of the previous RCX-Studio Pro, supporting the operation of Yamaha robots from setup to maintenance.

- Emulator function

Checks the operation time by using the same data as actual machines. - Real-time tracing function

Robot status parameters such as the load factor of each axle and positioning checking can be monitored in real time. - Cycle time calculation function

The operation cycle time between two points can be calculated quickly. - Data comparison function

The difference between two specified data sets can be displayed visually. Direct comparison with online data is also possible, enabling significant reductions in maintenance time.

Specifications

|

Product names |

RCX-Studio 2020 Pro |

RCX-Studio 2020 Basic |

| Product codes1 |

KCX-M4990-50 |

KCX-M4990-40 |

| License management |

USB key (purple) |

USB key (blue)2 |

| Compatible languages |

Japanese, English, Chinese |

|

| OS3 |

Microsoft Windows 7 SP1 (32/64bit), 8.1 (32/64bit), 10 (32/64bit) |

|

| Operating environment |

.NET Framework 4.5 or higher |

|

| CPU |

Recommended: Intel Core i5 2GHz or higher; Minimum: Intel Celeron 2GHz or higher; with 3D sim disabled: Intel Core2 Duo 2GHz or higher |

|

| Memory |

Recommended: 8GB or more; Minimum: 4GB or more; with 3D sim disabled: 1GB or more |

|

| Hard disk space |

1GB or more of free space on the computer where RCX-Studio 2020 is to be installed |

|

| Communication ports |

Communication cables: Serial port, Ethernet, or USB port |

|

| Others |

Dedicated communication cable (for D-Sub, or for USB) |

|

| Compatible controllers |

RCX340/RCX320 |

|

| Compatible robots |

Yamaha robots which can be connected to the RCX340/RCX320 |

|

1: Software package product codes. Both of the software products can be downloaded from our website.

2: Common with the previous RCX-Studio Pro.

3: Windows 7, Windows 8.1, and Windows 10 are trademarks or registered trademarks of Microsoft Corporation in the United States and other countries. Other company or product names listed are trademarks or registered trademarks of the respective companies.

About YAMAHA Robotics FA Section

Yamaha Factory Automation Section (FA Section), a subdivision of Yamaha Motor Robotics Business Unit in Yamaha Motor Corporation, is focused on delivering flexible, high-accuracy industrial robots for precision automation challenges.With its roots in the introduction of robot technology to Yamaha motorcycle assembly activities, the division has over 40 years’ experience solving automation challenges from factory-scale to micron-level. Yamaha’s industrial robots are now trusted by leading corporations worldwide, in activities as diverse as semiconductor fabrication and assembling electronic products, domestic appliances, automotive components, and large liquid-crystal panels.

Yamaha FA Section offers a unified range of solutions for robotic assembly, including single-axis robots, SCARA, cartesian, and articulated robots. Innovations such as the LCM100 linear conveyor module; a smoother, space-saving and more versatile successor to conventional belt and roller conveyors continue to set the pace in factory automation. Core robotic technologies as well as key components and complete robot systems are all produced in-house, ensuring consistent quality and control over lead-times.

Headquartered in Hamamatsu, Yamaha FA Section serves customers globally through its worldwide sales network spanning China, Taiwan, Korea, south Asia, north America, Australia/New Zealand, and Europe.

www.yamaha-motor-im.eu

Contact info

Oumayma Grad

Marketing Communications Manager

Hansemannstraße 12

41468 Neuss

Germany

Office: +49 2131 2013 538

Mobile: +49 1517 0233 297

Fax: +49 2131 2013 550

Email: oumayma.grad@yamaha-motor.de

Web: www.yamaha-motor-im.eu