Yamaha Motor Robotics FA Section will show visitors to Motek 2022 its family of compact, affordable industrial robots boost the productivity of common component-handling and product-assembly processes.

Topical demonstrations at Yamaha’s booth, 7515 in hall 7, will present SCARA, cartesian, and single-axis robots, and the LCMR200 linear conveyor module, highlighting their speed, accuracy, and flexibility.

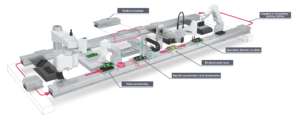

The LCMR200, which has programmable direction, speed, acceleration, and stop positions, solves workpiece-transport challenges in robot assembly cells as well as manual production lines. At Motek, Yamaha will combine LCMR200 units with a cartesian robot to show how parts can be quickly moved between processes. The LCMR200 allows robots to work on items without first removing them from the module, which can save engineering costs and reduce cycle time.

Yamaha LCMR200

Also at Motek this year, an automated bonding demonstration will show SCARA and cartesian robots working together to accelerate adhesive deposition and ensure precision assembly. In addition, single-axis robots from the Yamaha Robonity series will show how they can address numerous applications for transport, feeding, and general process automation throughout today’s factories. The slim units are designed with high rigidity and a low centre of gravity for rock-solid automation and highly repeatable positioning. The Robonity lineup includes models with up to 1100mm stroke length and up to 2400mm/s excursion speed.

Yamaha’s affordable YK-XE SCARA range, which allows a low cost of entry into flexible automation, will also be on display. The smallest YK-XE model has arm length of just 400mm, with 4kg maximum load handling, for moving and assembling small items with high positional accuracy. Three further models offer arm length up to 710mm and up to 10kg maximum load. The demonstration will combine the YK-XE robot with an Asycube bulk-parts sorter to assist with picking. The Asycube interface leverages software developed by Yamaha to integrate and coordinate the two systems.

Visitors can also see the software packages available to help select, simulate, and program robots in standalone or group configurations. They include the RCX-Studio 2020 for programming SCARA, cartesian, and LCMR200 systems, and a software toolkit for RCX3 series controllers. In addition, the Robonity controller and software tools for offline configuration and real-time performance monitoring ensure the best performance from single-axis robots.

Motek, the trade fair for automation in production and assembly, is in Stuttgart from October 4-7. Yamaha’s industrial robot experts will be available throughout the show to discuss the demonstrations and any further questions about applying advanced robots to solve today’s automation challenges.

For more information about Yamaha’s full range of industrial robots and associated software tools, please visit https://fa.yamaha-motor-robotics.de/.

ABOUT YAMAHA Robotics FA Section

Yamaha Factory Automation Section (FA Section), a subdivision of Yamaha Motor Robotics Business Unit in Yamaha Motor Corporation, is focused on delivering flexible, high-accuracy industrial robots for precision automation challenges.

With its roots in the introduction of robot technology to Yamaha motorcycle assembly activities, the division has over 40 years’ experience solving automation challenges from factory-scale to micron-level. Yamaha’s industrial robots are now trusted by leading corporations worldwide, in activities as diverse as semiconductor fabrication and assembling electronic products, domestic appliances, automotive components, and large liquid-crystal panels.

Yamaha Motor FA Section offers a unified range of solutions for robotic assembly, including single-axis robots, SCARA, cartesian, and articulated robots. Innovations such as the LCMR200 linear conveyor module; a smoother, space-saving and more versatile successor to conventional belt and roller conveyors continue to set the pace in factory automation. Core robotic technologies as well as key components and complete robot systems are all produced in-house, ensuring consistent quality and control over lead-times.

Headquartered in Neuss, Germany, Yamaha FA Section serves customers in all Europe.