Yamaha Robotics Factory Automation section has successfully helped a customer drive up productivity and quality by changing the way electronic assemblies are transferred between production processes.

Building electronic assemblies using automated processes can maintain a consistent line rate as circuit boards are assembled, inspected, and tested before packaging and shipping. If production needs to be increased, the usual approach is to install faster equipment or more assembly lines, which can demand significant financial investment and factory floorspace.

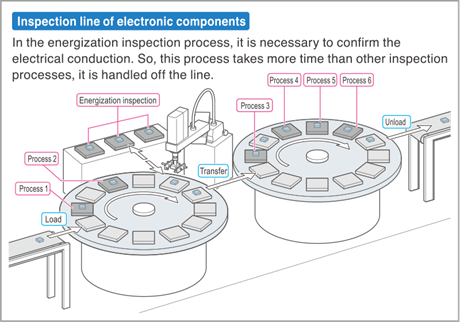

However there can be another way, as one Yamaha customer discovered, by focusing on how built-up assemblies are presented for end-of-line inspection. In this instance, the customer’s production department had set up two circular indexing tables – a proven, accurate solution for workpiece transport, familiar to generations of production engineers – to move electronic assemblies through a sequence of end-of-line quality controls. These controls include an electrical test that requires powering-up the boards, which takes a longer cycle time than other processes in the sequence.

Figure 1 below shows how the engineers arranged to handle the electrical testing offline to avoid slowing production, using a SCARA positioned between the two indexing tables. The SCARA loads the boards one at a time from the first table into offline testing stations and moves tested boards to the second table to complete the inspection sequence.

Figure 1. Inspection and test using indexing tables is complex and difficult to scale.

Figure 1. Inspection and test using indexing tables is complex and difficult to scale.

Production Bottleneck

As figure 1 shows, three offline stations operate in parallel to ensure the aggregate test cycle time matches the speed of the indexing tables. The fixed, sequential nature of the indexing prevents testing in parallel directly on the tables. On the other hand, unloading, testing, and reloading exposes units to the risk of damage during handling, which can impair quality.

When the production team sought to increase output, to meet growing market demand for the company’s products, this offline testing became a bottleneck that needed to be addressed. The engineers first considered the obvious option, to increase capacity by using larger index tables that can handle bigger pallets containing multiple boards instead of one. In practice, indexing with multi-unit pallets is difficult to adjust and the units must still be moved into offline testing. They decided to find a solution to increase production output as well as improving quality by preventing damage to the boards such as scratches that can occur as they are loaded and unloaded from offline testing.

The Search for a Solution

Tatsuro Katakura, Sales General Manager at Yamaha Robotics FA Section, takes up the story. “The team approached Yamaha at a trade show after seeing our booth demonstration featuring the LCMR200 flexible transfer system, including the traversing unit for creating branches within production lines. They saw the speed and flexibility they needed, especially with the traversing unit that makes it possible to perform the entire electrical testing inline. They were excited at the opportunity to increase throughput and overcome their handling challenges all at the same time.”

The LCMR200 system (figure 2) is powered with linear motors, which are fast, quiet, and extremely flexible. The modules let factory designers build production lines their way by configuring up to 64 individually controllable and identifiable sliders. Each module has its own built-in driver that simplifies installation and minimizes wiring. Workpieces are retained in pallets, trays, or other tooling fixed to the sliders and production processes can be performed without unloading workpieces from their tooling as the sliders have a maximum payload of 30kg and positional repeatability is ±5µm. This relieves handling, saves time, and reduces the engineering costs involved to design and implement the line.

The sliders allow bidirectional movement, with programmable acceleration, deceleration, and start/stop positions, without sensors or mechanical stoppers, giving flexibility to ensure optimum production speed and efficiency. The speed of each slider can be set independently up to 2500mm per second, with variable speed control between work stations. All the sliders, as well as any peripheral robots such as SCARA machines that may be used to perform assembly processes, can be controlled through a PLC from a single Yamaha YHX controller using standard profiles that eliminate writing ladder logic. A choice of vertical and horizontal circulation units lets sliders return quickly to the start of the production line.

Traversing Module

With the traversing module, designers can add branches in the production line or retract individual units without interrupting automation or slowing the line rate. This makes it possible to bypass optional processes, customize or personalise individual items efficiently, deal with bottlenecks by performing processes in parallel, isolate units for sampling, or divert to a quarantine area for correction or rework. “The traversing unit is a powerful part of the LCMR200 system that combines convenience and modularity with efficiency and adaptability,” confirms Tatsuro Katakura.

In this application, the traversing unit let the team create three branches to perform electrical testing inline (figure 3), relieving the bottleneck to throughput and avoiding the handling risks associated with unloading and reloading the units for testing. Also, the LCMR200 sliders provide enough room to carry pallets containing four items to be inspected and tested simultaneously. Compared with the indexing table system that handles each unit in a cycle time of 4.5 seconds, the LCMR200 line inspects and test four items at once in 3 seconds. This enabled the factory to double its output in one-third of the time, effectively meeting its expanded production target in a single daytime shift of eight hours. In contrast, production using indexing tables had been operating continuously 24 hours per day.

Conclusion

“This project delivered an extremely satisfying result, enabling our customer to boost production and increase quality while also relieving stress on equipment as well as staff by reducing the number of working hours,” concludes Tatsuro Katakura. “The traversing unit demonstrated the benefits of its branching capabilities very clearly, simplifying the production line as well as protecting the assemblies against handling hazards. The LCMR200 system is an excellent solution for production teams that are facing speed, space, and scalability barriers.”

About Yamaha Robotics FA Section

Yamaha Factory Automation Section (FA Section), a subdivision of Yamaha Motor Robotics Business Unit in Yamaha Motor Corporation, is focused on delivering flexible, high-accuracy industrial robots for precision automation challenges.

With its roots in the introduction of robot technology to Yamaha motorcycle assembly activities, the division has over 40 years’ experience solving automation challenges from factory-scale to micron-level. Yamaha’s industrial robots are now trusted by leading corporations worldwide, in activities as diverse as semiconductor fabrication and assembling electronic products, domestic appliances, automotive components, and large liquid-crystal panels.

Yamaha Motor FA Section offers a unified range of solutions for robotic assembly, including single-axis robots, SCARA, cartesian, and articulated robots. Innovations such as the LCMR200 linear conveyor module; a smoother, space-saving and more versatile successor to conventional belt and roller conveyors continue to set the pace in factory automation. Core robotic technologies as well as key components and complete robot systems are all produced in-house, ensuring consistent quality and control over lead-times.

Headquartered in Neuss, Germany, Yamaha FA Section serves customers in all Europe.

www.yamaha-motor-robotics.eu

#DiscoverYamahaRobotics